Productos

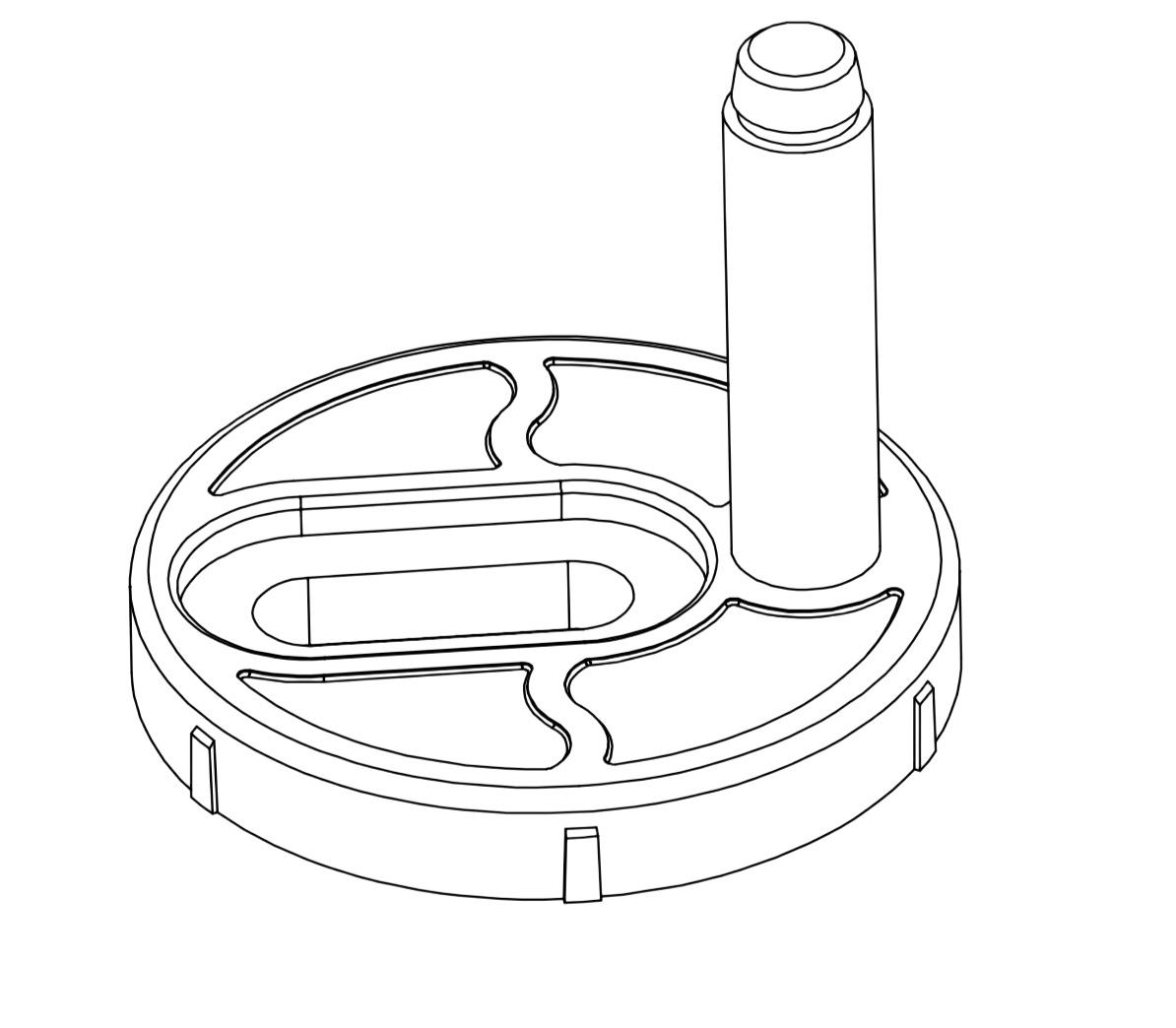

Nuestros juegos de fijación están diseñados para brindar confiabilidad y facilidad de instalación. Cada juego incluye componentes duraderos diseñados para garantizar un ajuste seguro y estable, evitando cualquier movimiento. Con fabricación de precisión y materiales de calidad, nuestros juegos de fijación son ideales para una variedad de aplicaciones de artículos sanitarios. Disfrute de una instalación sin complicaciones y de un rendimiento estable y duradero con nuestros juegos de fijación diseñados por expertos.

Artículo No :

LY-HD45-01Orden (MOQ) :

1000El paquete incluye :

2 x cover plate, 2 x rubber washer,2 x fixing screw, 2 x anchorColor :

CustomizablePuerto de embarque :

SHANGHAITiempo de espera :

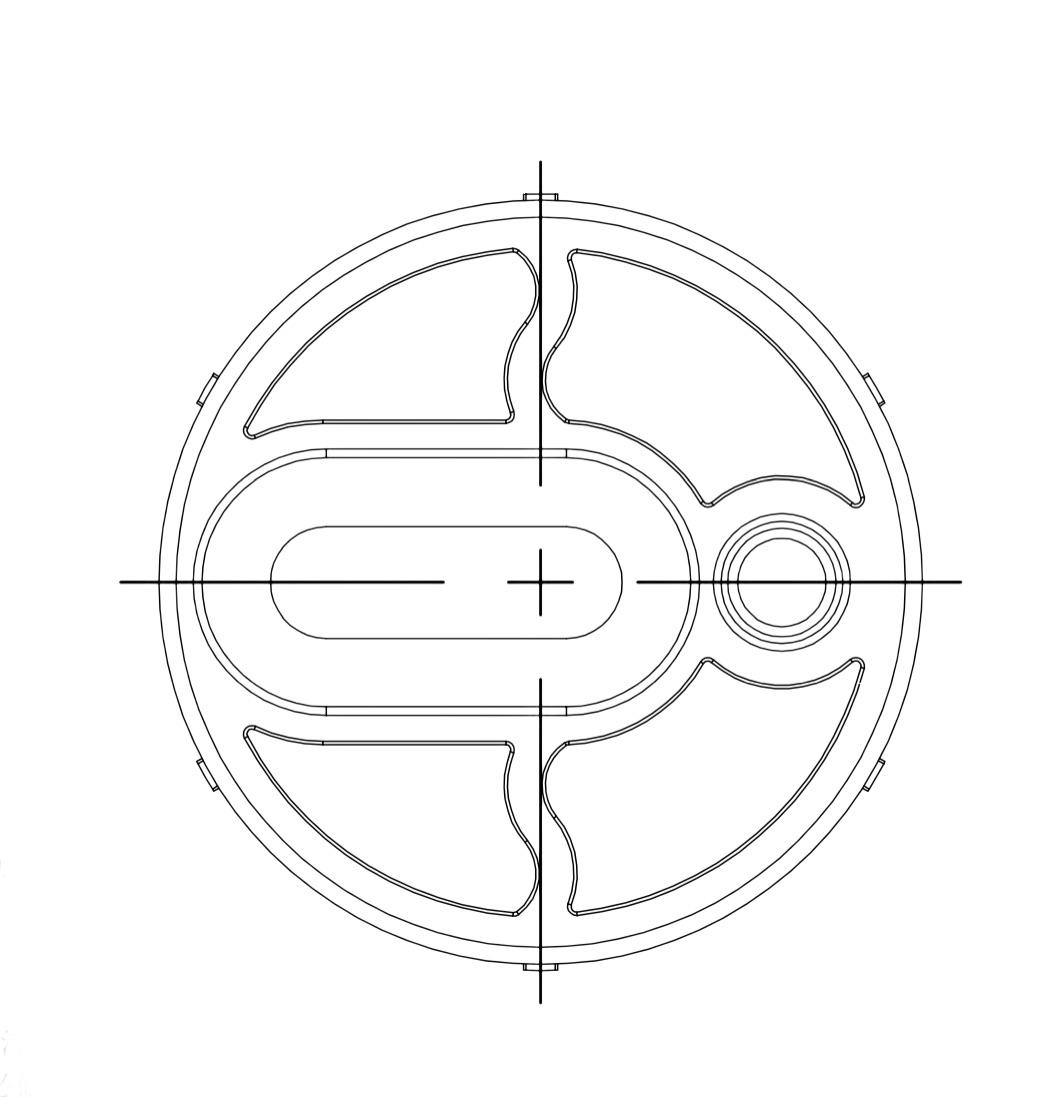

15-25 DAYSDiámetro :

45mm,50mm,60mm

![]()

Main body: SUS304 (Stainless Steel)

Additional components: POM, PA66, Brass

![]()

![]()

TYPE:Fixing set for toilet seat cover

FEATURE:Quick release, easy installation

Nail Tightness test 13000times

Neutral Salt Spray Test 96 hours

Acetic Acid Salt Spray 48 hours

Screws Tightening 3.0-5.0Nm

Hardness of rubber Shore A 70±5

Load Testing 600N

| Fixing set for toilet seat cover |

| FEATURE |

| TYPE | Fixing set for toilet seat cover |

| FEATURE | Quick release, easy installation |

| Nail Tightness test | 13000times |

| Neutral Salt Spray Test | 96 hours |

| Acetic Acid Salt Spray | 48 hours |

| screws tightening | 3.0-5.0Nm |

| Hardness of rubber | Shore A 70±5 |

| Load Testing | 600N |

![]()

1. Smooth Base Surface: The base surface should be flat and even, without any bumps or irregularities.

2. The product's surface should be free of any burrs, sharp edges, or other defects.

3. Stainless steel rivets must pass a 10kg tensile force test; no detachment is allowed.

4.Ensure that the components and materials match as specified in the 3D drawings.

5. All products must pass quality control checks, including visual inspection and functional testing, before shipment.

6.Packing should be free of holes, broken edges, and cracks.

1.Insert the bolts into the seat hinges.

2.Align the seat with the mounting holes on the toilet bowl.

3.Insert the bolts through the holes from above.

4.Secure the seat by placing washers and nuts onto the bolts and tightening them with a screwdriver and wrench.

5.Ensure the seat is properly aligned before fully tightening the nuts.

6.Snap on any provided bolt covers for a clean, finished look.

DIRECCIÓN : No. 9, Renmin East Road, Industrial Concentration Zone, Chenbao Town, Xinghua City, Jiangsu Province

Derechos de autor

2023 © Taizhou Longway Moulding Technology Ltd Reservados todos los derechos

. Mapa del sitio

| Blog

| Xml | política de privacidad  RED SOPORTADA

RED SOPORTADA